Special technical features

We always offer our customers innovative state-of-the-art solutions that guarantee safe, efficient and economical processes. The secret of our success is very simple: We listen to you. Through experience and further development in the field of winding technology, we are constantly generating solutions that ensure optimal work processes and are already part of our standard.

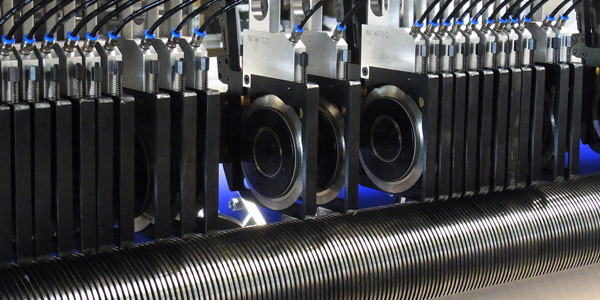

Automatic knife adjustment

- Fully automatic setting of each individual cutting blade, controlled via the control panel

Longitudinal cut

- Inline cutting with up to 51 cutting blades (depending on material)

- Available as scissor cut, crush cut or razor cut

- Also in combination with automatic knife adjustment

Edge trim rewinder (stand alone or inline)

- Changing (alternating) winding of the edge strip

- Changing (alternating) winding of the edge strip

- Conical winding shaft with flanges

- Material thicknesses from 50 μm up to 200 μm

- Very low web tensions possible 4-25 N

- Winding speed up to 100 m/min.

Automatic core loading and positioning

- Fully automatic core loading (optionally with pre-connected core cutter)

- Fully automatic core positioning on the winding shaft, with and without distance between the cores, position adjustable on the control panel

Banderoling Device

- Freely selectable format sizes

- Freely selectable position on the finished roll

- For inline production of finished rolls

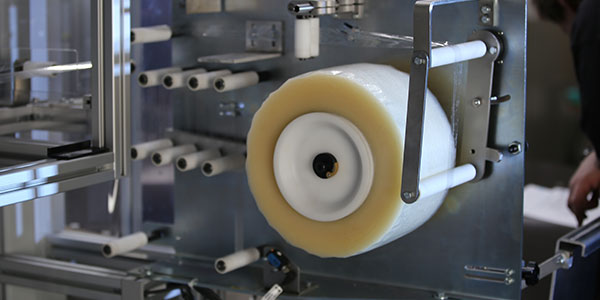

Spool Dispenser

- For the use of alternately wound tape spools for long running times

- Purely mechanical design without drive

- Change tape spools while machine is running

- Combination of taping and simultaneous banderoling of e.g. consumer information

Folding unit C-folding

- Mechanical double C-folding unit

- In combination with centre cut for individual repeats with single C-folding

Perforation-Einheit

- Inline perforation system with quickly and easily exchangeable perforation blades

- Adjustable sheet length without blade exchange

- Single-sheet length can be saved in the recipe

Handling aid / Finger stripes

- Automatic generation of the handling aid / finger stripes for adhesive materials by applying a non-adhesive strip e.g. tape-roll start